Why Choose Tempered Cover Glass for Machinery Protection?

发布时间:

2025-07-09 14:35

来源:

Huize Glass

Why Choose Tempered Cover Glass for Machinery Protection?

Key Highlights

- Unmatched Durability: Tempered cover glass offers incredible strength and longevity, making it ideal for machinery protection.

- Enhanced Safety Features: When shattered, tempered cover glass breaks into small, harmless pieces, significantly reducing injury risks.

- Versatility in Industrial Applications: From packaging learn more and shipping to printing machinery, its adaptability knows no bounds.

- Superior Temperature Resistance: Perfect for environments with extreme heat or cold fluctuations.

- Customisation Options: Tailored solutions for various types of machinery and equipment, ensuring optimal fit and performance.

Introduction

Choosing tempered cover glass for machinery protection is a smart decision. This high-strength material offers exceptional durability that far surpasses regular glass. Whether you're safeguarding machinery in packaging facilities or protecting printing equipment, tempered glass provides unmatched resilience and safety. Its ability to withstand extreme conditions and maintain integrity ensures consistent reliability. Are you looking for reliable protection for your machinery? Contact us for a custom solution huizeglass tailored to your specific needs.

Key Benefits of Tempered Cover Glass for Machinery Protection

Tempered cover glass is a game-changer in machinery protection. Its remarkable durability and resistance to harsh conditions enhance both machinery longevity and operator safety. This makes it perfect for industries where packaging and heavy-duty equipment are used.

Additionally, its versatility benefits diverse industries—from printing machinery to shipping applications—ensuring consistent performance regardless of environmental challenges. The material’s protective qualities make it indispensable, reducing repair costs and downtime. Need tailored tempered glass solutions? Get in touch huizeglass for customised designs.

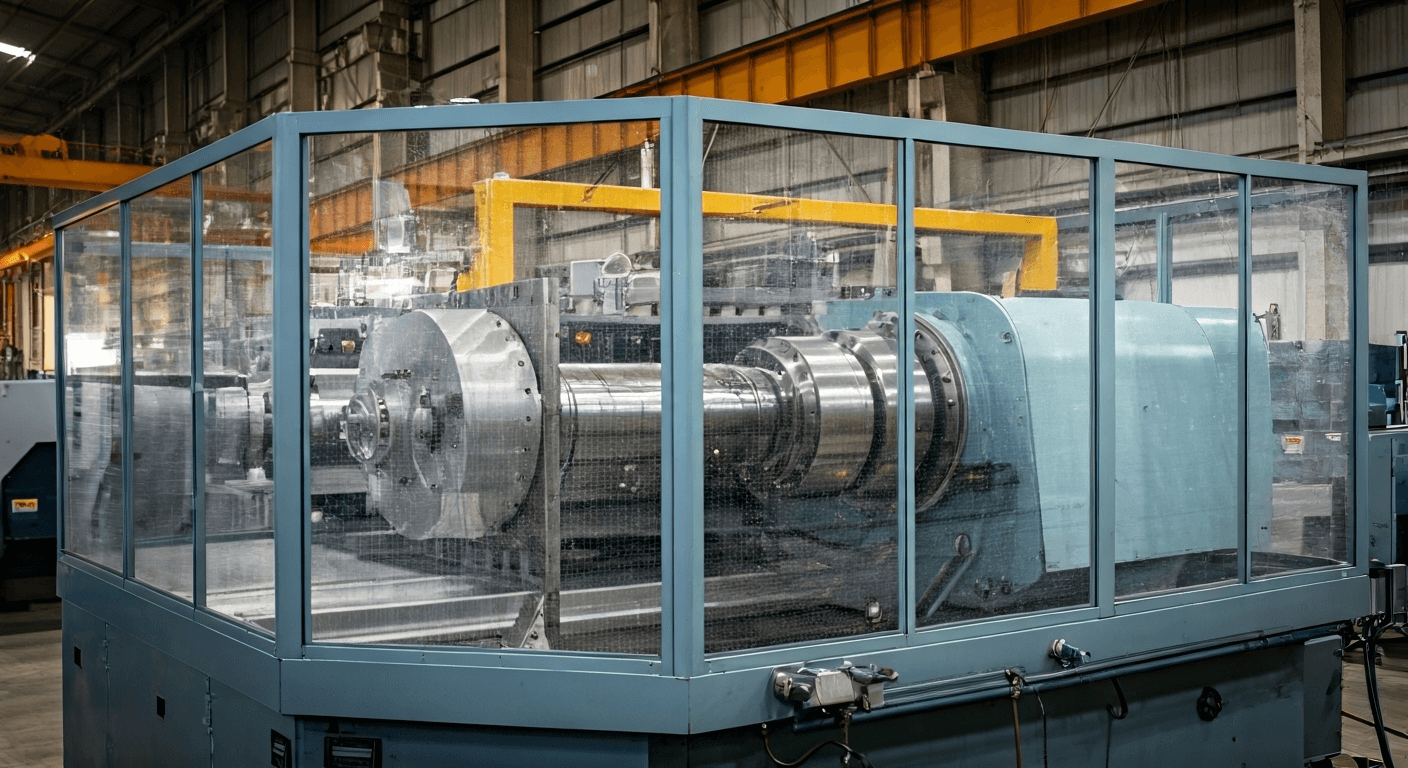

Superior Strength and Durability Compared to Standard Glass

One standout feature of tempered cover glass is its unparalleled strength compared to regular annealed glass. Industrial machinery often faces tough conditions, and tempered glass protects against mishaps like breakage and impact damage. Whether you're packaging heavy materials or handling shipping demands, this superior material excels in robust environments.

A unique advantage lies in its manufacturing process. Tempered glass undergoes thermal treatments that dramatically increase its resistance to wear and tear. Unlike regular glass, it retains its integrity under stress, making it ideal for machinery windows and control panels.

Enhanced Safety Features for Industrial Applications

Safety is critical in any industrial setting, and tempered cover glass is a leader here. Its unique property of breaking into small, blunt pieces minimizes injury risks, unlike sharp fragments from regular glass. This is especially vital for high-risk environments like mining and printing machinery.

Another aspect of its safety features is its resilience against operational pressures, ensuring that when it does break, it operates as needed within safe limits. Protective windows and control panels made from tempered glass shield both operators and equipment.

By integrating tempered glass into industrial applications, companies not only improve safety but also enhance equipment functionality. For packaging and shipping needs, this added security is indispensable. Ready to upgrade your machinery safety? Explore our custom solutions.

Conclusion

In summary, tempered cover glass stands out for its exceptional strength and safety features, making it the ideal choice for machinery protection. By opting for this advanced glass solution, you enhance not only the durability of your equipment but also ensure the safety of your operators in an industrial setting. Its customizable nature allows you to tailor the glass to fit specific machinery needs, resulting in optimized performance. Don't compromise on protection; choose tempered cover glass to safeguard your investments. For a tailored solution that meets your requirements, get in touch with us today for quotes and commercial inquiries!

Frequently Asked Questions

What makes tempered cover glass different from regular glass?

- Tempered cover glass undergoes thermal treatments to enhance strength and resilience. Unlike regular glass, it withstands extreme conditions and shatters into harmless fragments, ideal for packaging, shipping, printing machinery, and more. Learn more on Wikipedia.

Is tempered cover glass suitable for all types of machinery?

- Yes, its adaptability makes it perfect for diverse machinery. From shipping systems to printing machinery, tempered cover glass offers tailored solutions that improve safety and durability. Explore its uses on huizeglass.

How does tempered cover glass improve operator safety?

- It reduces injury risks by shattering into blunt, tiny pieces instead of sharp shards during breakage. Perfect for high-risk machinery applications like packaging and printing info here.

Can tempered cover glass be customized for specific equipment?

- Yes, tempered cover glass can be tailored in shape, size, and thickness to match specific machinery needs. Options like anti-glare coatings or different tempering types ensure precise solutions. Contact huizeglass for customization.

How do I order custom tempered cover glass for my machinery?

- Visit huizeglass.com to request a quote and share your machinery specifications. We accept credit card payments and offer secure shipping and packaging services for your custom glass.

Related News