Discover Low Iron Glass: What Sets It Apart?

发布时间:

2025-06-21 12:04

来源:

Huizeglass

Low Iron Glass vs. Standard Glass: What’s the Difference?

Key Highlights

- Low iron glass contains very low amounts of iron, offering exceptional clarity and color neutrality compared to standard clear glass.

- Standard clear glass has a natural green tint, caused by higher iron levels in its composition.

- The visible light transmittance of low iron glass is significantly higher than that of standard float glass.

- Both types serve diverse uses, from decorative glass to large-scale architectural projects.

- Low iron glass is highly preferred for display cases, facades, and interior applications requiring maximum transparency.

- Leading brand names such as Guardian, Pilkington, and Starphire represent the pinnacle of high-performance low iron glass in the market.

Introduction

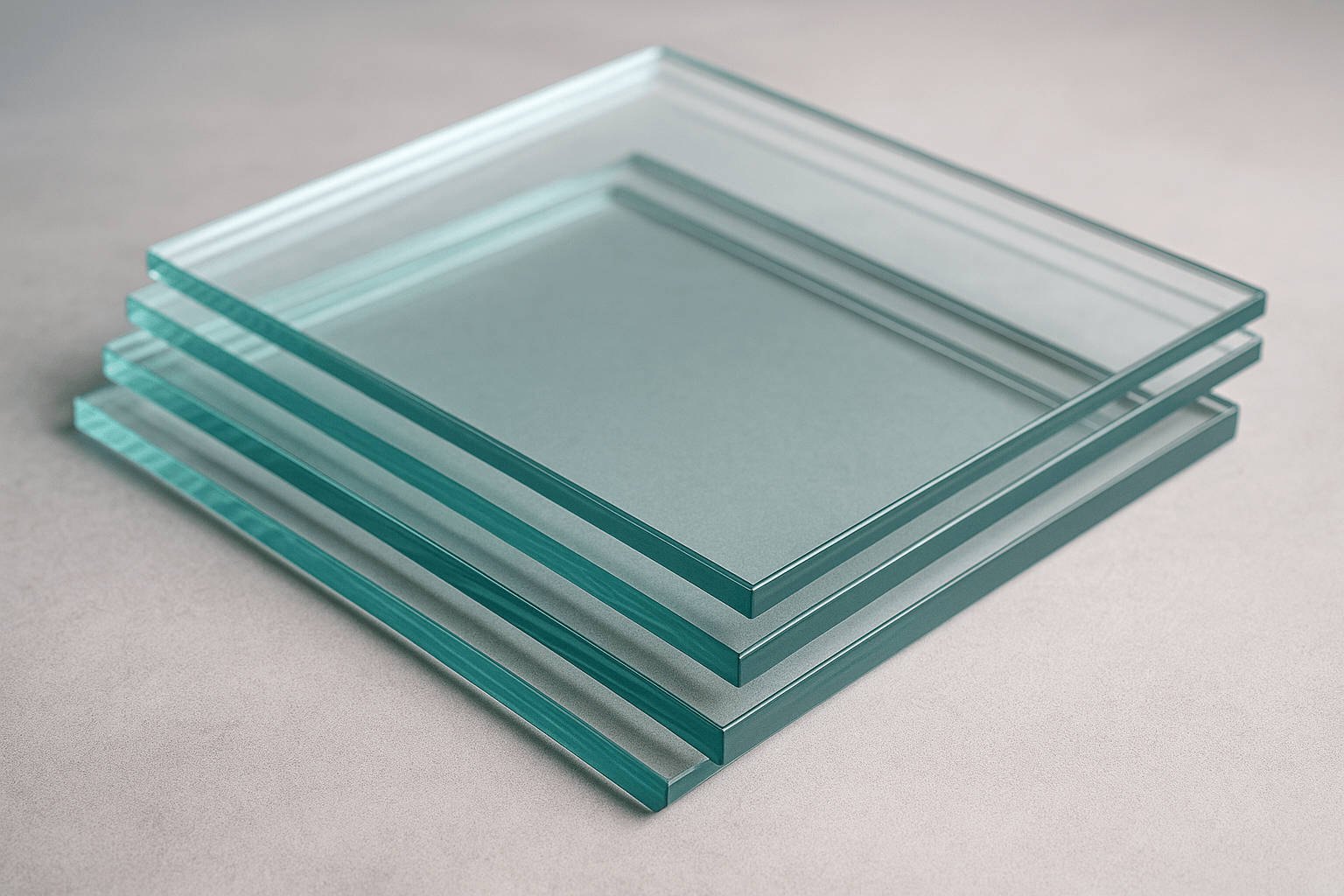

Glass is a big part of today’s architecture and interior design. People care about how it looks and how well it works. Standard clear glass has more iron in it. This makes it look greenish. So, this type is not good if you want the glass to be very clear and full of color. On the other hand, low iron glass has less iron. This kind gives you exceptional clarity and good color neutrality, so light moves through it much better. You can see its effect in interior partitions or in big architectural projects. Which one to use depends on what your project needs. Knowing how they differ will help you choose the right one.

Key Differences Between Low Iron Glass and Standard Glass

The main way that low iron glass and standard glass differ is in what they are made of. Standard clear glass has more iron in it, which gives the glass a greenish tint. You can notice this greenish tint more in thick glass. Low iron glass has less iron, so it has better color neutrality. This means things seen through it look like their real, natural colors.

Standard float glass is fine for most uses. But if you want high light transmission and very good clarity, low iron glass is better. People often use it for architectural facades, solar panels, and decorative work where seeing things clearly is important.

Iron Content and Composition

The iron levels in glass play a big role in how the glass looks and works. The way clear glass is made depends a lot on ferric oxide, which is found naturally in the raw materials. When iron levels go up, the glass looks greener.

| Glass Type | Iron Levels | Visible Effects |

|---|---|---|

| Standard clear glass | Higher iron content | Greenish tint noticeable, especially in thick glass |

| Low iron glass | Low ferric oxide levels | Exceptional clarity and color neutrality |

To make low iron glass, raw materials with less iron are picked first. The iron in the molten glass formula is watched closely so the glass will be very clear and look nice. This step brings down the iron and is what gives low iron glass its special look and transparency.

Low iron glass is used when people want clear and bright glass with no greenish tint. This is not something you get with ordinary plate glass.

Visual Clarity and Color Tint

When you look at glass up close, you notice its clarity and the color tint it has. These things depend a lot on how much iron is in the glass. Standard glass has a greenish tint that you spot even more when the glass is thick or you look at the edges.

But low iron glass gives you the best clarity, with almost no tint showing up. This type of glass keeps the colors you see true and clear. Light and objects appear just as they are, which is perfect for architectural projects and interior design where you want everything to look clean and natural.

Whether you are looking at float glass, decorative glass, or glass doors, the glass thickness will make these changes stand out even more. If you want clarity and not color distortion, low iron glass is your top choice. It gives you great transparency, especially when glass edges are on show. This makes low iron glass the best pick when your project needs that clear, sharp look.

Performance Characteristics of Low Iron Glass

Low iron glass gives you better results than most other types of glass. It lets in a lot of light. This helps when you want high light transmission and great visible light transmittance. It looks bright and clear. That is why low iron glass is good in places where you need a lot of natural light. For example, you see it used for solar panels and for building facades.

You can also customize glass solutions with low iron glass. There can be coatings or laminations added to give it more features, like thermal insulation. The versatility and reliable performance mean this glass fits into many different projects. It always helps you get better visibility and adds a touch of style and elegance too.

Light Transmission and Transparency

Light transmission is the key thing that sets low iron glass apart. It lets a higher amount of visible light pass through when you compare it to standard glass. This helps people feel more openness around them and makes the space look bright and full of life.

You will often see this glass used where there is a need for a lot of natural light. This includes building facades, solar panels, and large skylights. One more good thing is that it has high performance. So, it is a smart choice for designs that look to use more daylight and cut down on energy use.

Low iron glass also comes with great transparency. Anything behind it will look real and natural. With standard float glass you often get a greenish tint, which can change how colors look. Low iron glass gets rid of this, giving a clear view, which is why so many architects and designers pick it for a modern look and classy feel.

Durability and Applications

Low iron glass is strong and keeps its shape well, so it lasts for a long time. This makes it a good choice when you need glass to stay in place for many years.

Here are some common ways to use low iron glass:

Decorative glass is used in interiors for a clean and stylish look.

Partitions and glass doors help let in more natural light to brighten up a room.

Exteriors and facades use this glass to keep the design see-through and neat in many architectural projects.

Balustrades and flooring need thick glass that is both clear and safe at the same time.

This glass can take on a lot without giving up its clear look. It works well in different places, like inside homes or in big building projects where you want the most light transmission and want to reduce bends or marks in the glass. So, whether you care about how it works or how it looks, low iron glass offers both clarity and style for many lighting needs, from glass doors and facades to partitions and exteriors.

Conclusion

To sum up, it is important to know the differences between low iron glass and standard glass before you pick the right one. Low iron glass gives you better clarity and more light transmission. This makes it the top choice if you want the best look in your home or work project. It has less color tint and is very sturdy, so it works well in many places, both at home and in businesses. If you want low iron glass that fits what you need, reach out to us today. We can help you and show what options are best for your project.

Frequently Asked Questions

What is the main advantage of low iron glass over standard glass?

- Low iron glass gives you better clarity and shows colors more truly than regular glass. This kind of glass has less iron in it. That means there is less green tint. You get better light transmission and the glass looks clearer. This is a good pick if you want your glass to look nice and let in a lot of light. It works well in places where the look and the light quality both matter.

Is low iron glass more expensive than regular glass?

- Yes, low iron glass will cost more than regular glass. This is because it gives you better clarity and is more pure. There are not as many things in the glass that can change the way it looks. Making low iron glass is also a bit harder, and that is why the price is higher.

Can low iron glass be customized for specific projects?

- Yes, you can change low iron glass to fit your project. You can pick the thickness, size, and shape you want. This glass is flexible, so it can work for many types of uses. It looks good and works well in building designs.

Where is low iron glass most commonly used?

- Low iron glass is often used when clarity and light transmission are very important. You will see it in high-end designs, retail displays, and solar panels. It is also used for aquariums. This type of glass has less green tint than regular glass. It looks clear and sharp. That is why people pick it for premium and good-looking projects.

How do I order customized low iron glass? (Include CTA to contact for customization)

To get low iron glass made just for you, get in touch with a trusted supplier. Give them the details you want, like the size and any special features. If you need help or want a price, contact us today. We will talk about your project and what you need.

Related News