How to Tell if Glass is Tempered: 5 Simple Methods

发布时间:

2025-09-04 17:47

来源:

Huize glass

Key Highlights

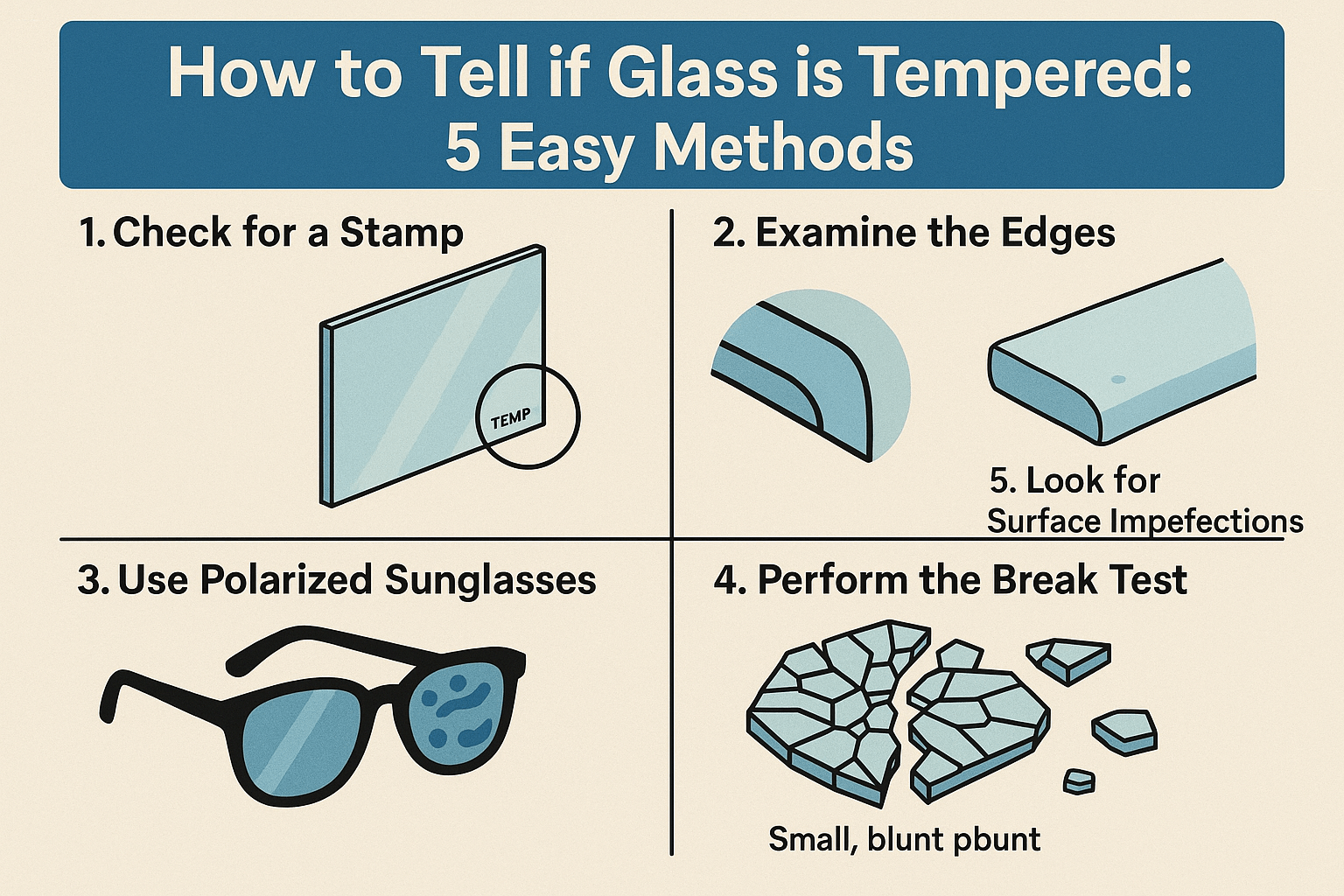

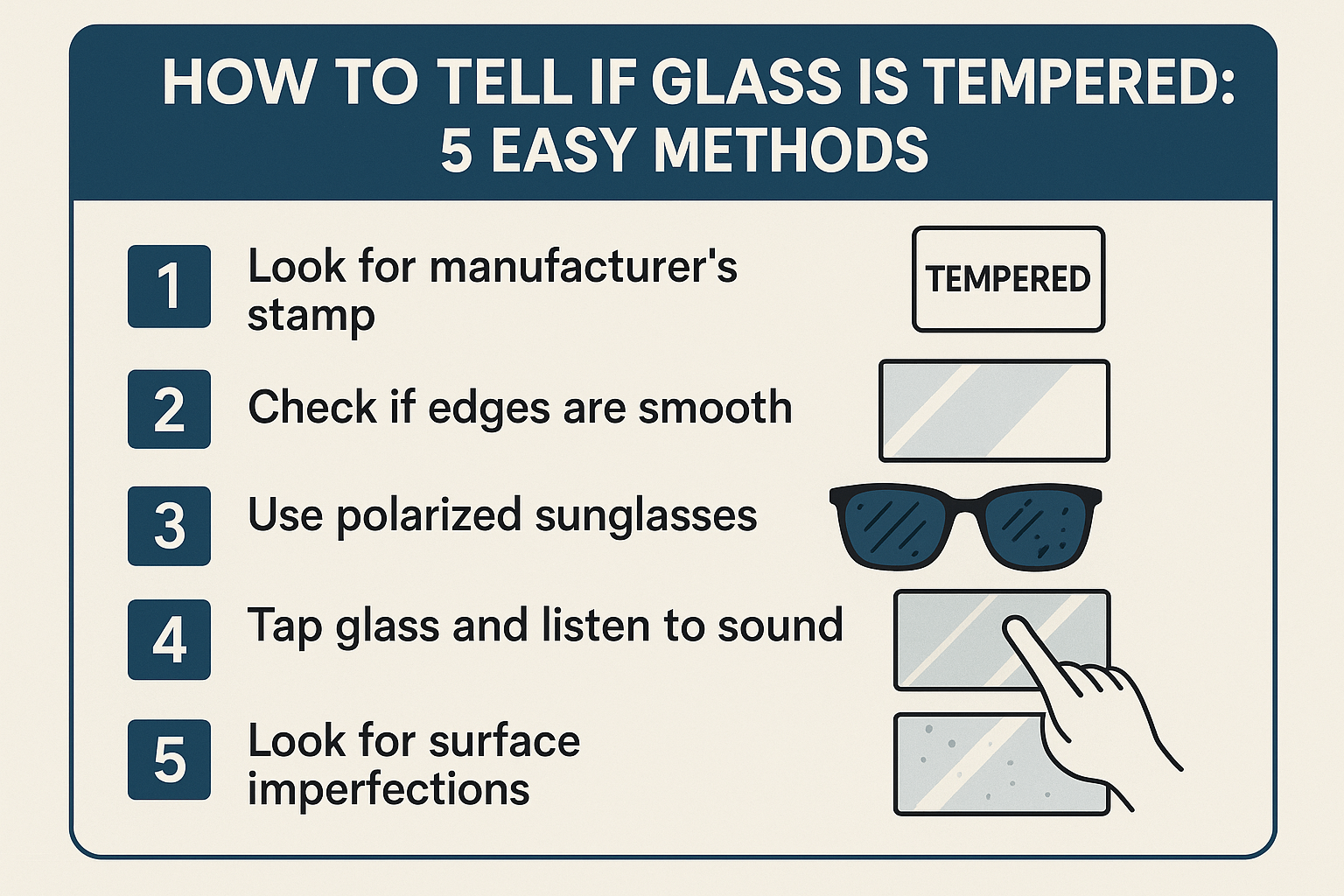

- You can identify tempered glass by looking for a small manufacturer's stamp in the corner.

- The edges of tempered glass are always perfectly smooth, unlike the sharper edges of regular glass.

- When viewed through polarized sunglasses, tempered glass will show dark, shady lines or spots caused by thermal stress.

- Tempered glass is a type of safety glass that shatters into small, blunt pieces instead of dangerous shards.

- Minor imperfections on the glass surface are often a tell-tale sign of the tempering process.

- Pay attention to the glass edges and look for a stamp to quickly determine the glass type.

Introduction

Have you ever wondered if the glass in your windows, doors, or tabletops is strong enough to handle daily life? Knowing how to tell if glass is tempered is crucial for ensuring safety in your home or business. Tempered glass is much stronger than regular glass and breaks in a much safer way. This guide will walk you through five easy methods to identify this superior safety glass, helping you confirm that your installations meet necessary safety standards and provide peace of mind.

Tempered Glass vs. Regular Glass: Key Differences

The primary difference between tempered glass and regular glass lies in strength and safety. Tempered glass is designed for durability and is about four to five times stronger than standard, or annealed, glass. This makes it an excellent choice for high-traffic areas or applications where impact is a risk.

When it comes to breakage, the contrast is even more stark. Regular glass shatters into large, dangerous, sharp shards that can cause serious injuries. In contrast, tempered safety glass is engineered to crumble into small, granular, and relatively harmless blunt pieces, significantly reducing the risk of harm.

What Makes Tempered Glass Unique?

The unique properties of tempered glass come from a specialized manufacturing method. The tempering process involves heating the glass to extremely high temperatures, upwards of 600 degrees Celsius, and then subjecting it to a rapid cooling process with high-pressure air jets. This quick change creates high compression on the surface and tension in the core of the glass.

This internal stress is what gives tempered glass its incredible strength. It allows the glass to withstand much greater force and thermal shock than regular glass. If you mistake regular glass for tempered glass in a project, you run the risk of it shattering into dangerous shards under stress, which could lead to severe injuries or property damage.

Ultimately, this process ensures that if the glass ever does break, it fails in a predictable and safe manner. Instead of large, sharp shards, it crumbles into small, pebble-like blunt pieces, which is why it's considered a safety glass. This characteristic is the most significant benefit of using tempered glass in your home or business.

Common Uses and Safety Benefits

Because of its enhanced strength and safety features, tempered glass is required by building codes for many applications. You'll commonly find this durable glass type in places where human impact is more likely, ensuring a safer environment for everyone. Its unique properties make it the ideal choice for a wide range of uses.

Some of the most common applications include:

- Shower doors and tub enclosures

- Patio doors, windows, and skylights

- Glass tabletops and shelves

- Vehicle windows

The primary benefit is, of course, safety. The way it breaks minimizes the risk of injury, making it essential for homes with children and pets, as well as public spaces. Tempered glass panels also look different around the edges; they are perfectly smooth and rounded, unlike the sharp, unfinished edges of regular glass, adding another layer of safety and a polished aesthetic.

Visual Signs: How to Quickly Recognize Tempered Glass

How can you quickly identify tempered glass without special tools? The easiest way is to perform a simple visual inspection. There are a few key giveaways you can look for on the glass surface that signal it has been treated for durability and safety.

Start by searching the corners of the glass panes for a manufacturer’s stamp or etching. Additionally, looking closely at the surface for minor imperfections can also indicate that you are dealing with a piece of glass that has been tempered. These quick checks can often give you an immediate answer.

Checking for a Manufacturer’s Stamp or Etching

The most definitive way to identify tempered glass is to look for a stamp, often called a "bug." Manufacturers place a small, permanent marking in one of the corners of the glass to certify that it meets safety standards. Is there a specific marking or stamp on tempered glass that I should look for? Yes, this stamp usually includes the manufacturer's name and the safety standard it complies with, such as "CPSC" (Consumer Product Safety Commission) or "ANSI."

If you find this etching, you can be certain you have the right glass type. However, sometimes the stamp can be hidden by the window frame or may have worn away on older glass. A missing stamp doesn't automatically mean the glass isn't tempered, but its presence is a guaranteed confirmation.

For a clearer understanding, here are the key visual differences:

| Feature | Tempered Glass | Regular (Annealed) Glass |

|---|---|---|

| Edges | Perfectly smooth and even | Sharp and may have slight ridges |

| Stamp | Often has a small etched stamp in the corner | No stamp or safety certification |

| Surface | May have slight waves or tiny imperfections | Typically flawless and flat |

| Breakage | Crumbles into small, dull-edged pebbles | Shatters into large, jagged shards |

Surface Patterns, Distortions, and Edge Appearance

Beyond a stamp, how can you visually identify tempered glass versus regular glass? Look closely at the surface in the light. The tempering process can leave behind subtle imperfections that are key identifiers. These are not flaws but rather byproducts of the manufacturing process.

You might notice faint waves or "shady lines" across the glass surface. These are created by the rollers that move the glass through the heating furnace. In addition, you might spot tiny blemishes or marks on the surface, which occur when microscopic particles are sealed onto the glass during heating.

Here’s what to look for:

- Strain Pattern: A "wavy" or distorted appearance when viewed from an angle.

- Minor Imperfections: Small scratches or specks that are fused to the surface.

- Thickness and Clarity: While not always obvious, tempered glass can sometimes have a slightly different clarity or thickness due to the treatment it undergoes.

Method 1: Inspect the Glass Edges & Corners

One of the simplest and most reliable hands-on methods is to examine the glass edges. The finishing on the edges of tempered glass is distinctly different from that of regular glass. Do tempered glass panels look different around the edges compared to regular glass? Absolutely, and this difference is easy to feel.

Run your finger carefully along the edge of the glass. If it feels perfectly smooth and uniform, you are likely dealing with tempered glass. The corner of the glass will also feel rounded and finished, a direct result of the manufacturing process that is necessary before the glass is heated.

Differences in Edge Finish Between Tempered and Regular Glass

The reason for the difference in edge finish lies in the production process. All cutting, drilling, and edging must be done before the glass is tempered. Once it undergoes the heating and cooling cycle, it cannot be altered. Because of this, manufacturers ensure the edges are perfectly finished and safe to handle beforehand. This results in smooth, touchable edges.

Regular, or untempered, glass is simply cut from a larger sheet and often has sharp, unfinished edges that can easily cause cuts. If you were to compare the two side-by-side, the difference in the edge finish would be immediately apparent. The edges of regular glass panes can feel raw and slightly chipped from the cutting process.

This distinct smoothness is a key characteristic. While tempered glass breaks into blunt pieces, the edges of an intact pane are just as safe to the touch, providing a clean and polished appearance that regular glass lacks.

Why Edge Appearance Matters for Identification

The appearance of the edges is a crucial clue because it directly reflects the manufacturing journey of the glass. Since tempered glass cannot be cut after it's been strengthened, the pristine edge appearance confirms that the piece was fabricated to its exact size and then treated. It's a fundamental part of what makes it a finished safety glass product.

This tactile test helps you determine the type of glass without any special tools. It's a reliable indicator that is consistent across different applications, whether you're checking a tabletop, a shower door, or a window pane.

Here’s why it’s so important:

- It confirms the glass was prepared for tempering.

- It distinguishes it from regular glass, which is often cut to size on-site.

- The smooth surface of the edge is a safety feature in itself.

Method 2: Light Polarization & Sunglasses Trick

Can using polarized sunglasses help you find out if glass is tempered? Yes, it's a clever and effective trick. This method works by revealing the hidden strain pattern created during the tempering process. These patterns are invisible to the naked eye but become visible when viewed through polarized lenses.

To try this, put on a pair of polarized sunglasses and look at the glass surface on a sunny day. You should see dark, shadowy lines or spots that are characteristic of tempered glass. This is one of the most reliable ways to identify tempered glass when there is no visible stamp.

Spotting Stress Patterns With Polarized Lenses

The stress pattern you see through polarized glasses is a direct result of the thermal stress induced during the rapid cooling phase of tempering. This process creates a pattern of tension and compression within the glass that isn't visible under normal light. Polarized lenses filter light in a specific way, making these areas of internal strain visible.

When you look at a piece of tempered glass through the lenses, these patterns often appear as a series of dark lines or dots spread across the surface. This effect is sometimes noticeable on car side windows when you're wearing sunglasses.

What to look for:

- Dark, shadowy lines that form a grid-like pattern.

- Spots or blotches that appear and disappear as you tilt your head.

- A "quilted" look on the glass surface.

If you see any of these patterns, you can be confident that the glass is tempered. Annealed, or regular, glass will not show any strain pattern and will simply look darker through the lenses.

Step-by-Step Guide to Using a Flashlight and Sunglasses

If you're not in direct sunlight, can shining a flashlight help you confirm if a window is made of tempered glass? Yes, you can simulate the effect with a bright light source. A smartphone's flashlight or another LCD screen can work just as well.

Here’s how to do it step-by-step:

- Hold a white screen (like a tablet or laptop) or shine a flashlight on one side of the glass pane.

- From the other side, look at the glass through a pair of polarized sunglasses.

- Tilt your head from side to side or rotate the sunglasses. As you do, look for the appearance of dark lines or spots on the surface.

These surface patterns are the strain lines unique to tempered glass. If the pane simply looks darker with no discernible patterns, it is likely not tempered. This method helps improve the clarity of the patterns, making them easier to spot even in low-light conditions.

Method 3: Tap Test and Listening for Sound Differences

Another simple, though less definitive, method is the tap test. This involves listening for sound differences when you gently tap the glass. Due to its internal structure and tension, tempered glass produces a different sound than regular glass. Are there any simple tests to tell if aquarium glass is tempered? The tap test can be a good starting point for items like aquariums where other methods might be difficult.

Gently tap the center of the pane with a coin or your knuckle. Tempered glass tends to produce a clearer, higher-pitched ringing sound, while regular glass gives off a duller, shorter thud. Listen carefully, as the difference can be subtle but noticeable.

How Tapping Reveals Tempered Glass Structure

The unique sound of tempered glass comes from its internal structure. The tempering process creates immense tension in the core of the glass, which makes it much more rigid. When you tap it, this internal stress causes it to vibrate at a higher frequency than regular glass. The result is a sound that is more resonant and musical.

In contrast, regular glass lacks this internal tension. It vibrates at a lower frequency, producing a flat, dull sound. To better notice the sound differences, it helps to have a known piece of regular glass nearby to use as a comparison.

Here's a simple breakdown:

- Tempered Glass: Produces a clearer, ringing tone.

- Regular Glass: Produces a dull thud.

While this test can be a helpful indicator, its reliability can be affected by the size of the glass, its thickness, and how it is mounted.

Limitations and Safety Tips When Performing Tap Tests

While the tap test is easy to perform, it has its limitations. The sound can be muffled by a tight frame or mounting, making it difficult to distinguish the sound differences accurately. It’s also a subjective test, as what sounds like a "ring" to one person might sound like a "thud" to another.

It is crucial to be gentle. Never tap the glass with excessive force, as you could cause it to crack or break, regardless of the glass type. Tempered glass is strong, but it's not indestructible, and a sharp impact could risk failure.

Safety tips to remember:

- Tap gently in the center of the glass, away from the edges.

- Use a small, light object like a coin, not a heavy or sharp tool.

- Never attempt destructive tests. Is it safe to try cutting a piece of glass if I'm unsure it's tempered? No. Attempting to cut tempered glass will cause it to shatter instantly.

Conclusion

In conclusion, identifying tempered glass is essential for safety and functionality. By employing the methods outlined in this blog, such as inspecting edges, using polarized lenses, and performing the tap test, you can confidently determine whether your glass is tempered or not. Remember, the visual signs and specific techniques discussed will not only help you in various settings but also enhance your understanding of glass types and their applications. If you have any questions or need further assistance regarding glass identification, feel free to get in touch with us for personalized guidance. Your safety and satisfaction are our priorities!

Frequently Asked Questions

What if the glass has no markings—is there another way to verify it is tempered?

If there is no stamp or manufacturer’s etching, you can still verify the glass type. Examine the edges for a smooth finish or look for surface imperfections. The most reliable method without a stamp is using polarized sunglasses to spot the tell-tale strain patterns unique to tempered safety glass.

Is it safe to try cutting glass if I’m unsure whether it’s tempered?

No, you should never attempt cutting or drilling glass if you suspect it might be tempered. If it is safety glass, it will not cut cleanly like regular glass but will instead shatter into thousands of small pieces, which can be dangerous and will ruin the pane.

Can these methods help identify tempered glass in aquariums or windows?

Yes, these methods work for most flat glass applications, including aquariums and windows. The tap test and polarized sunglasses trick are particularly useful for identifying tempered glass panes in installed windows, while inspecting the edges can be effective for aquariums or frameless glass panels.

Related News