Discover Anti-Reflective Coating for Glass Solutions Today

发布时间:

2025-09-23 17:19

来源:

huizeglass

Key Highlights

Here are the key takeaways about custom anti-reflective coating solutions:

- An anti-reflective coating dramatically reduces reflections on glass, transforming your viewing experience.

- It improves light transmission to over 98%, offering unparalleled clarity and brightness.

- Unlike standard reflective glass, it minimizes distracting glare for a clearer, more natural view.

- The technology works by using ultra-thin layers to cause destructive interference of light waves.

- Custom solutions are available for a wide range of applications, from storefronts to residential windows.

- It differs from anti-glare coatings, which diffuse light rather than eliminating reflections.

Introduction

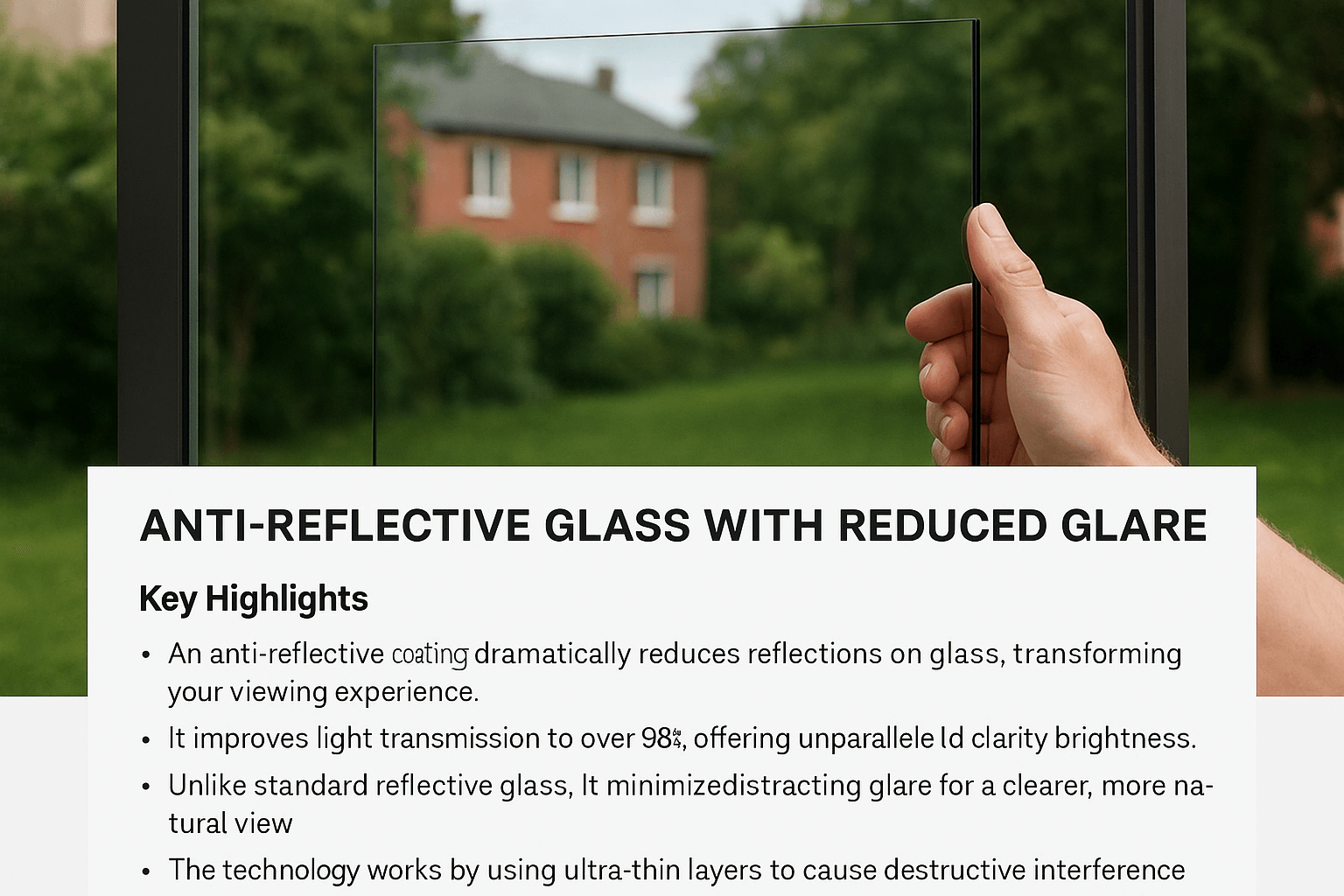

Have you ever looked through a window only to see your own reflection staring back? Standard reflective glass can often spoil the view with distracting light reflection. This common issue can turn a beautiful vista into a mirror, especially at night or in brightly lit spaces. The goal of glass is to provide a clear window to the world, but reflections create a paradox. Fortunately, advanced coatings are changing the game, promising a flawless viewing experience free from these interruptions.

Understanding Anti-Reflective Coating for Glass

An anti-reflective coating for glass is a sophisticated application of optical physics designed to enhance your viewing experience. It involves applying microscopic layers to the glass surface that manipulate how light waves behave upon contact. This technology is a game-changer for anyone seeking crystal-clear views.

Instead of just scattering light, an AR coating is engineered to nearly eliminate reflections. This results in glass that is almost invisible, allowing true colors and details to shine through without distortion. Let's explore how this works and how it compares to other treatments.

What Is Anti-Reflective Coating and How Does It Work?

An anti-reflective coating is a specialized optical coating applied to the surface of glass to minimize reflections. While standard glass can reflect up to 8% of light, AR-coated glass can reduce this to as low as 0.6%. This significant reduction maximizes light transmission, making the glass appear more transparent.

The magic behind this technology is a principle called destructive interference. The coating consists of multiple thin layers with varying refractive indices. As light hits the coated surface, reflections from the different layers cancel each other out. This prevents the reflected light from reaching your eyes, creating a much clearer view.

You have likely already seen this technology in action. It is commonly used on high-end eyeglasses and professional camera lenses to reduce glare and improve image contrast. The same principle provides stunningly clear views for architectural glass, displays, and more.

Anti-Reflective vs Anti-Glare Coatings: Key Differences

While people often use the terms interchangeably, anti-reflective coating and anti-glare coating work in fundamentally different ways. The primary goal of an AR coating is to maximize light transmission and reduce reflectance from the glass surface itself.

An anti-glare coating, on the other hand, uses a different approach. It creates a textured surface that diffuses reflected light. This reduces the "shine" or glare from external light sources like the sun or indoor lighting, but it can also slightly reduce the transparency and clarity of the view.

Here’s a quick breakdown of their key distinctions:

- Mechanism: AR coatings cancel out light waves, while anti-glare coatings scatter them.

- Clarity: An AR coating provides maximum clarity and transparency, while anti-glare can create a slightly hazy or matte finish.

- Reflection: AR coatings minimize reflections from the glass itself, creating an "invisible" effect. Anti-glare reduces the intensity of bright, specular reflections from external sources.

Types of Anti-Reflective Coatings for Glass

Not all anti-reflective coating options are created equal. The type of AR coating needed depends on the specific application, the glass substrates being used, and the target wavelength of light. From simple single-layer applications to complex multi-layer solutions, the technology can be tailored to meet precise performance requirements.

Whether for a commercial storefront or a high-tech optical lens, choosing the right coating is key to achieving premium quality results. Understanding the difference between the main types will help you select the perfect solution for your project's needs.

Single-Layer and Multi-Layer Coatings Explained

The simplest form of AR coating is single-layer coatings. As the name suggests, this involves applying one thin layer of material, often magnesium fluoride, to the glass. This layer's thickness is optimized for a specific wavelength of light, typically in the middle of the visible spectrum. While effective, its performance diminishes for other colors or wavelengths.

For superior performance, multi-layer coatings are used. These sophisticated coatings consist of alternating layers of materials with different refractive indices. By carefully designing these stacks, manufacturers can achieve extremely low reflectance (less than 0.1% in some cases) across a broad range of wavelengths, such as the entire visible spectrum. This makes them ideal for applications demanding the highest clarity and color fidelity.

Here is a table comparing the two:

| Feature | Single-Layer Coatings | Multi-Layer Coatings |

|---|---|---|

| Performance | Good for a specific wavelength | Excellent across a broad spectrum |

| Reflectance | Reduced to ~1% | Can be reduced to <0.1% |

| Complexity | Simpler and less expensive | More complex and costly |

| Best For | Basic applications, cost-sensitive projects | High-performance needs (e.g., displays, high-end optics) |

Specialty and Custom Solutions for Unique Applications

Beyond standard window applications, custom solutions for anti-reflective coatings are available to meet the demands of various industries. These specialty coatings are engineered for specific functions, ensuring optimal performance where clarity and visibility are critical.

For instance, solar panels use AR coatings to maximize the amount of light that reaches the photovoltaic cells, increasing their efficiency. High-end camera lenses and optical instruments rely on multi-layer coatings to eliminate stray light and improve image contrast. Digital display screens in bright environments use AR coatings to remain readable and vibrant.

Other unique applications include:

Museum showcases to provide unobstructed views of artifacts.

Car showroom windows to present vehicles without distracting reflections.

Zoo enclosures to create a more immersive viewing experience.

Picture frames to protect artwork while ensuring true color representation.

Ready to find the perfect custom solution for your project? Contact us today to discuss your specific needs.

Benefits of Anti-Reflective Coating on Glass

The advantages of using an anti-reflective coating for glass extend far beyond simply reducing reflections. The primary benefit is improved clarity and visibility, as the coating allows more light to pass through the glass. By minimizing reflectance, it creates a view that is sharper, brighter, and more natural.

In addition to visual enhancements, these coatings can contribute to a building's overall performance. When combined with other technologies, they can boost energy efficiency and occupant comfort. Let's look closer at how these benefits play out in both aesthetics and functionality.

Improved Clarity, Visibility, and Aesthetics

The most striking benefit of an anti-reflective coating is the dramatic improvement in clarity and visibility. By reducing reflections to less than 1%, the glass becomes virtually invisible. This allows for an uninterrupted connection between indoor and outdoor spaces, making views feel more immersive and expansive.

Unlike reflective glass which can act like a mirror, AR-coated glass ensures that your focus remains on what's beyond the pane. This technology can achieve a light transmission of over 98% and a color rendering index (CRI) of 99. According to Guardian Glass, a leading manufacturer, this means "the colors you see through the glass are almost exactly those you see without glass." [1]

This level of performance significantly enhances the aesthetics of any space. For retail stores, it means products are displayed in their true colors without distracting reflections. For homes, it means picture-perfect views of your garden or cityscape, day and night.

Energy Efficiency and Comfort for Residential & Commercial Spaces

Can a coating designed for clarity also improve energy efficiency? Absolutely. While an AR coating itself doesn't block heat, it is often combined with other high-performance glass products in an insulating glass unit (IGU). This combination allows you to achieve low reflection and excellent thermal performance simultaneously.

An IGU, also known as an insulated glass unit, typically consists of two or more panes of glass separated by a sealed air or gas-filled space. When one of these panes features an anti-reflective coating and another has a low-emissivity (low-E) coating, you get the best of both worlds: a crystal-clear view and superior insulation.

This synergy offers several benefits for both homes and businesses:

- Enhanced Comfort: The IGU helps maintain stable indoor temperatures year-round.

- Lower Energy Bills: Improved insulation reduces the load on heating and cooling systems.

- UV Protection: Laminated or coated glass within the IGU can block harmful UV rays.

- Uncompromised Views: You don't have to sacrifice clarity for thermal efficiency.

Customisation and Application Options

The versatility of anti-reflective coatings allows for extensive customisation to suit nearly any application. Whether you need to treat a large architectural facade or a small display case, the coating process can be adapted. The technology is applied directly to the glass surface during manufacturing to ensure durability and optimal performance.

This flexibility means that bespoke solutions are available for a wide range of industries, each with unique requirements for clarity, durability, and aesthetics. From windows and displays to more specialized uses, customisation is key to unlocking the full potential of anti-reflective glass.

Can You Apply Anti-Reflective Coating to Existing Glass?

A common question is whether an AR coating can be added to existing glass installations. The answer is generally no, at least not with the same high-quality results as a factory-applied coating. The process for creating a durable, high-performance AR coating is highly technical and performed in a controlled environment.

Methods like physical vapor deposition or e-beam evaporation are used to bond microscopic layers to the surface of glass. [2] This process requires the glass to be exceptionally clean and is integrated into the manufacturing line. Applying a coating on-site to existing windows would not provide the same durability, clarity, or longevity.

While some spray-on or film products claim to reduce reflections, they cannot match the performance or lifespan of a professionally manufactured AR coating. For the best results, it is always recommended to specify AR-coated glass during the initial design and construction phase or to replace existing panes with new, factory-coated glass.

Bespoke Solutions for Different Industries (Windows, Displays, Solar, More)

The true power of anti-reflective coating for glass lies in its adaptability. Bespoke solutions are engineered to meet the specific challenges of different industries, ensuring optimal performance for every application. By tailoring the coating, we can enhance everything from commercial windows to high-tech displays.

In retail, for example, storefronts and car showrooms use AR glass to give customers a perfectly clear view of products, free from distracting reflections that can obscure details. In museums, it protects valuable artifacts while making them appear as if there is no glass at all.

Here are just a few industries that benefit from custom AR glass:

- Architecture: For facades, viewing platforms, and residential windows that demand stunning clarity.

- Electronics: For digital displays, touch screens, and signage that must be readable in all lighting conditions.

- Energy: For solar panels, where maximizing light absorption is crucial for efficiency.

- Hospitality: For restaurants and hotels wanting to provide guests with unobstructed views.

Care, Maintenance & Product Longevity

Proper care and maintenance are essential for ensuring the product longevity of your anti-reflective glass. Although modern coatings are known for their impressive durability, following a few simple guidelines will keep your glass looking crystal-clear for years to come. Unlike delicate treatments of the past, today's AR coatings are robust and designed for real-world use.

However, using the right cleaning techniques and materials is still important to prevent accidental scratches or damage. Let's cover the best practices for upkeep and discuss the expected lifespan of these advanced coatings.

Cleaning and Upkeep Tips for Anti-Reflective Glass

Maintaining your anti-reflective glass is straightforward. The key to proper cleaning and upkeep is to be gentle and avoid abrasive materials that could harm the AR coating. Many modern AR-coated surfaces even include a hydrophobic and oleophobic top layer, which repels water and grease, making them easier to clean than standard reflective glass.

When cleaning is necessary, always start by removing any loose dirt or grit with a soft brush or by rinsing with water. This prevents scratching the surface during the wiping process. Use a mild, non-abrasive cleaning solution and a soft, lint-free cloth, such as a microfiber towel.

For best results, follow these simple tips:

Never use abrasive cleaners, scouring pads, or razor blades on the coated surface.

Avoid ammonia-based cleaners, which can damage some coatings over time.

Use a clean, soft microfiber cloth to wipe the surface dry to prevent water spots.

For stubborn spots, apply a small amount of isopropyl alcohol to a soft cloth and gently wipe the area.

Lifespan and Durability: How Long Does the Coating Last?

When investing in anti-reflective coating, a primary concern is its lifespan and durability. You'll be glad to know that factory-applied AR coatings are incredibly resilient. Materials like magnesium fluoride are hard-wearing, and the vapor deposition process creates a strong bond with the glass. This ensures excellent product longevity.

A high-quality anti-reflective coating is designed to last for the entire lifetime of the glass product it is applied to. Under normal conditions and with proper care, the coating should not peel, crack, or degrade. It is a permanent enhancement, not a temporary finish.

Because of this exceptional durability, you will not need to reapply the coating. If the coating is severely damaged by deep scratches or harsh chemicals, the glass panel itself would typically need to be replaced. However, for most residential and commercial applications, you can expect your AR-coated glass to maintain its performance and appearance for decades.

Sourcing & Working with Industry Leaders

To ensure you get the best results, it is crucial to source your anti-reflective glass from reputable suppliers. Industry leaders and specialized custom providers offer premium quality products that are tested and certified for performance. Working with experts guarantees that the glass meets your project's specific aesthetic and functional requirements.

Whether you're looking for products from leading brands or need a bespoke solution, the first step is to request a quote or consultation. This allows you to discuss your needs with a specialist who can guide you toward the perfect product.

Leading Brands and Custom Providers in Anti-Reflective Glass

When sourcing anti-reflective glass, you have the option of working with leading brands or specialized custom providers. Major manufacturers like Guardian Glass offer well-known product lines such as Clarity™, which are recognized for their exceptional performance and premium quality. These brands have invested heavily in research and development to deliver reliable and consistent results.

Alternatively, custom providers offer tailored services to create bespoke anti-reflective glass solutions. These companies, like ours, can work with you to develop a coating recipe optimized for your specific needs, whether it's for a unique architectural project, a scientific instrument, or a retail display. This approach provides maximum flexibility in terms of size, thickness, substrate, and performance characteristics.

Choosing the right partner is key. A reputable provider will offer technical support, performance data, and guidance to ensure you select the best possible solution. They can help you navigate options to achieve the perfect balance of clarity, durability, and cost for your project.

How to Request a Quote or Consultation [CTA]

Are you ready to transform your project with premium quality anti-reflective glass? Getting a quote or consultation is the first step toward achieving crystal-clear views. We make the process simple and are here to help you specify the perfect product, whether it's for a home in the Midlands or a commercial facade anywhere in the country.

Before reaching out, it is helpful to gather some basic information about your project. This will allow our team to provide a more accurate and timely response. The more details you can provide, the better we can tailor our recommendations to your needs.

To get started, follow these simple steps:

- Define Your Needs: What is the primary application (e.g., windows, display case, storefront)?

- Gather Specifications: Note the required glass dimensions, thickness, and any desired thermal or safety performance.

- Identify Performance Goals: Do you need to minimize reflections for a specific wavelength of light or across the entire visible spectrum?

- Contact Us: Reach out to our expert team at www.huizeglass.com to request your free quote or consultation. We are ready to help you see what's possible!

Conclusion

In summary, anti-reflective coatings are essential for enhancing the clarity and aesthetic appeal of glass in various applications, from residential windows to commercial displays. By understanding the different types of coatings and their unique benefits, you can make an informed decision for your specific needs. Custom solutions offer flexibility for diverse industries, ensuring that you receive a product tailored to your requirements. If you're ready to improve your glass solutions with high-quality anti-reflective coatings, don’t hesitate to reach out for a quote. Our experts are here to help you find the best options for your project.

Frequently Asked Questions

Is anti-reflective coated glass suitable for both homes and businesses?

Yes, anti-reflective coating is ideal for both homes and businesses. For businesses, it enhances product displays and storefronts by improving visibility. For homes, it provides stunning, unobstructed views and maximizes natural light, offering superior clarity compared to standard reflective glass.

Can anti-reflective coating be reapplied if worn?

Generally, you cannot reapply an anti-reflective coating. Factory-applied coatings are bonded to the glass surface for maximum durability and are designed to last the entire lifespan of the glass. If the coating sustains significant damage, the entire glass panel would need to be replaced.

Where can I buy high-quality anti-reflective coated glass?

You can purchase high-quality anti-reflective coated glass from leading brands or specialized custom providers like us. We offer premium quality solutions tailored to your project's needs. Whether you're in the Midlands or elsewhere, contact a reputable supplier for expert advice and to ensure the best performance.

Related News