How to Choose the Right Custom Glass Fabrication Service

发布时间:

2025-04-23 18:22

来源:

How to Choose the Right Custom Glass Fabrication Service for Your Architectural Project

Selecting the right custom glass fabrication service is a critical decision for the success of any architectural project. Whether you're designing a striking glass curtain wall, crafting sleek partitions for an office, or sourcing bespoke mirrors for a luxurious interior, the quality and suitability of your glass can make all the difference.

For architects, construction managers, and designers, the process of choosing a glass fabricator comes with several challenges, such as ensuring compliance with standards, navigating communication barriers, or finding the right type of glass and fabrication techniques. This guide will walk you through the key steps to identify the ideal partner for custom glass fabrication.

Understanding Your Project Requirements

Before reaching out to potential glass fabricators, it is essential to clearly define your project requirements. This ensures you're equipped to communicate your needs effectively and reduces the risk of misaligned expectations.

Define the Type of Glass Needed

Start by assessing the specific glass requirements for your project. Common types include:

- Tempered Glass: Durable and heat-resistant, ideal for doors, windows, and partitions.

- Laminated Glass: Provides added strength and safety, often used for railings, balustrades, or glass floors.

- Insulating Glass (IGU): Excellent for energy efficiency in facades and curtain walls.

- Low Iron Glass: Offers superior clarity, popular for display cases and high-end installations.

- Patterned Glass: Adds decorative textures for aesthetic appeal in interior spaces.

- Clear Glass: For a timeless, versatile look across a range of applications.

Specify Features and Dimensions

Clearly indicate the features your glass requires, such as thickness, edgework, coatings, or custom shapes. Be precise about dimensions to ensure seamless integration within your design.

Address Regulatory Compliance

Ensure the materials and processes comply with local building codes and certifications. This may include safety standards for tempered or laminated glass or performance requirements such as fire resistance or thermal insulation.

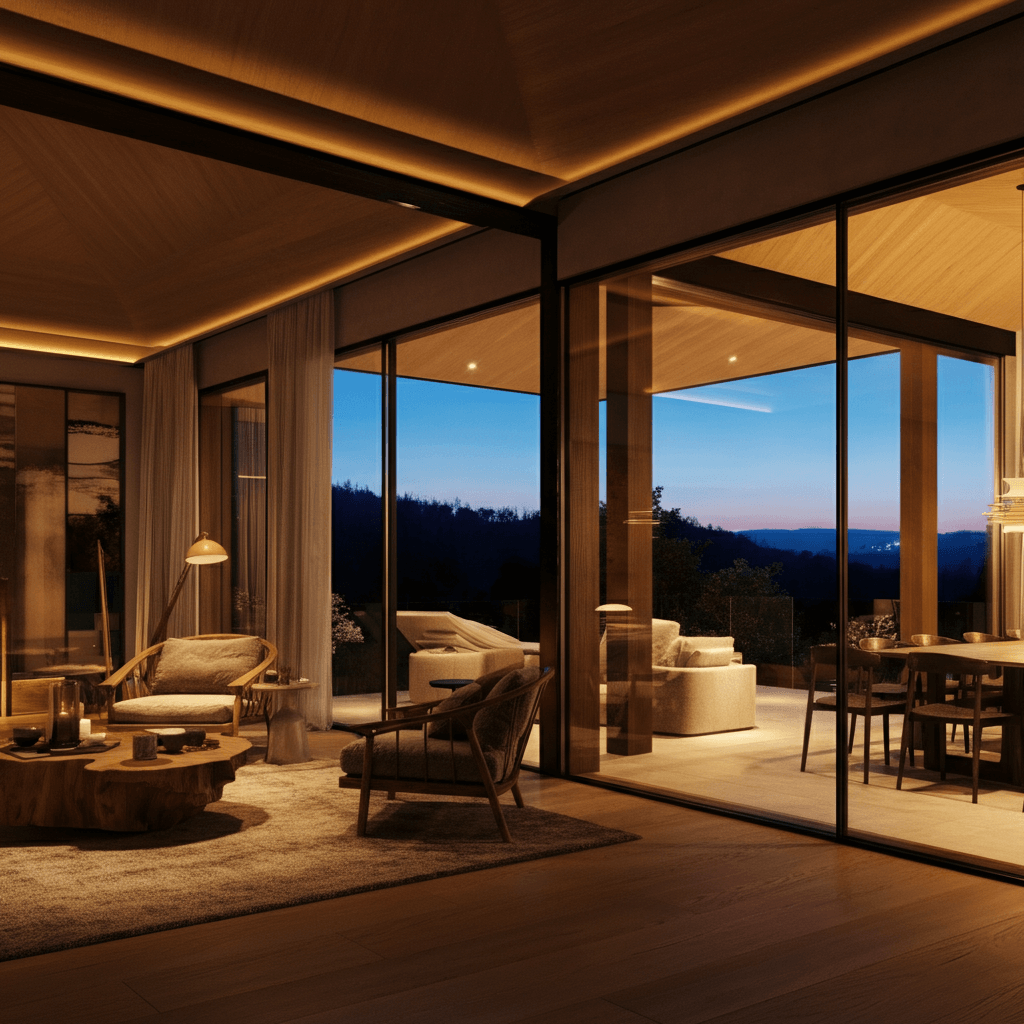

Consider Broader Applications

Glass can be utilized in various elements of an architectural project, such as:

- Interior decoration

- Furniture (e.g., tabletops or cabinetry)

- Doors and windows

- Curtain walls

- Bathroom mirrors

- Electronics (e.g., smart displays)

Having clarity on these project-specific needs will help you evaluate potential fabricators effectively.

Researching and Identifying Potential Fabricators

Finding the right custom glass fabricator begins with a thorough research process. Leverage the following methods to compile a list of potential partners:

- Online Directories and Industry Associations: Platforms such as the National Glass Association or local trade directories feature reputable glass fabricators.

- Referrals: Ask other architects, construction managers, or contractors for recommendations based on their experiences.

- Specialization Matching: Look for fabricators who specialize in the types of glass and fabrication techniques your project requires. For example, a facility experienced in intricate decorative glass might be better suited for artistic interiors, while those equipped with advanced tempering technology are ideal for structural applications.

Evaluating Fabricator Capabilities and Expertise

Once you’ve identified potential glass fabricators, assessing their capabilities and expertise is crucial to making an informed decision.

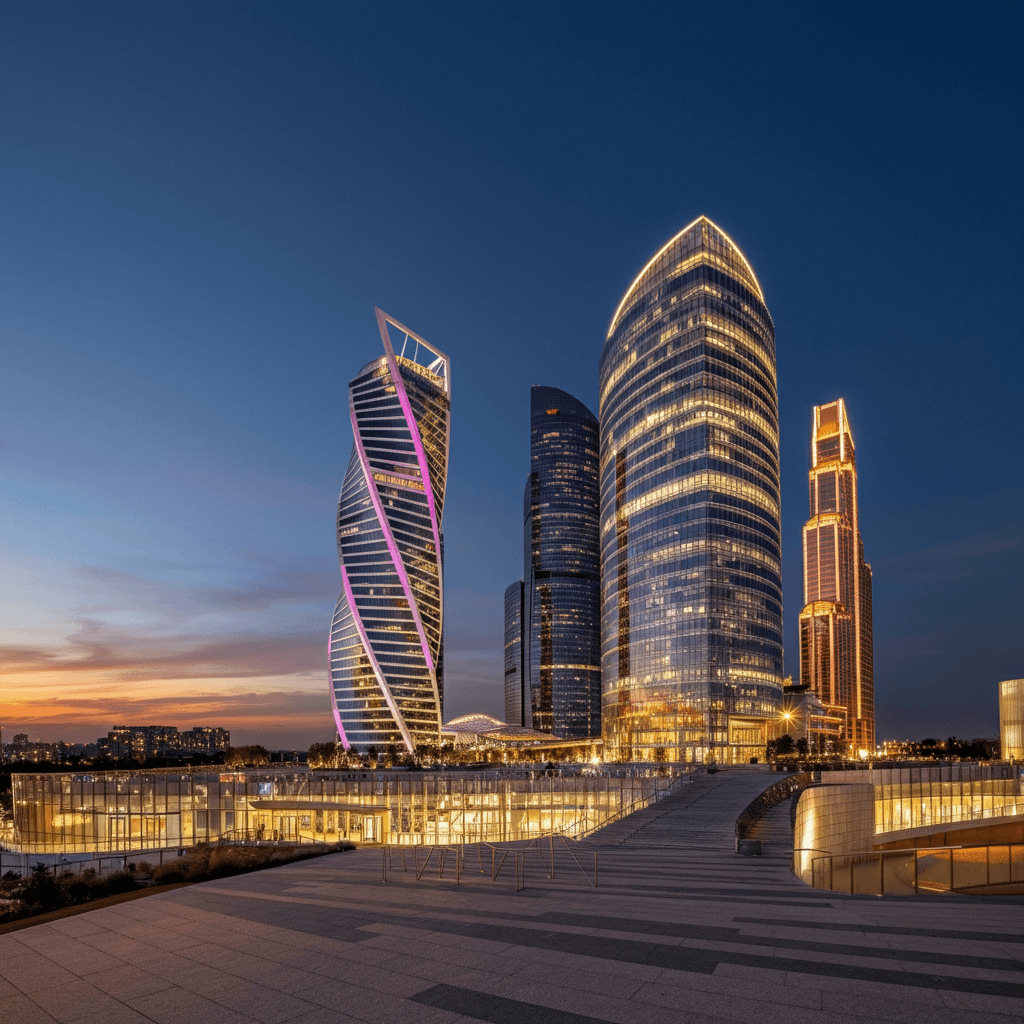

Assess Experience and Portfolio

Review their portfolio of past projects to determine if they have handled work similar to your requirements. Look for creativity, precision, and consistency in their completed projects. A fabricator experienced in large-scale curtain walls, for instance, may showcase installations demonstrating their ability to deliver quality on complex architectural challenges.

Certifications and Quality Control

Reputable fabricators are backed by certifications that demonstrate compliance with industry standards. Ask about their quality assurance processes, such as regular inspections, testing procedures, and documentation to ensure the durability and safety of fabricated glass.

Production Capacity and Lead Times

Discuss their production capacity to ensure they can meet your project's volume requirements efficiently. Ask about their lead times and verify their ability to deliver within your deadlines while maintaining quality.

Assessing Communication and Transparency

Smooth collaboration with a fabricator hinges on transparent communication and responsiveness.

Responsiveness to Queries

Fabricators who provide timely and detailed responses demonstrate their commitment to customer service. Avoid those who are slow to reply or dismissive of your concerns.

Clarity of Processes

Ask how they handle project changes, manage potential issues, and deal with quality control concerns. A reliable fabricator will have established processes for addressing challenges effectively.

Willingness to Collaborate

Good fabricators value open dialogue and collaboration. They should be willing to provide updates throughout the project and accommodate your design requirements wherever possible.

Requesting Quotes and Comparing Pricing

Cost is an important consideration, but it should not be the sole determinant. Follow these best practices during the pricing stage:

- Detailed Quotes: Request comprehensive quotes that break down costs for materials, labor, delivery, and any additional services.

- Compare Value: Assess not just the price but also the quality of materials, level of customization, and fabrication capabilities.

- Avoid Lowest-Price Pitfalls: Be cautious of significantly low quotes, as they may indicate shortcuts in quality or service.

Visiting the Fabrication Facility

A site visit can offer invaluable insights into a fabricator’s operational capabilities and commitment to quality.

Assess the Facility

Evaluate the equipment, production processes, cleanliness, and organization. Modern machinery and well-maintained facilities often indicate a capable fabricator.

Observe Quality Control Standards

Ask about their testing and inspection methods, and observe whether the facility adheres to safety and quality protocols.

Discuss Your Project

Use this opportunity to discuss your project in person. Address any remaining questions or concerns and gauge their interest and professionalism firsthand.

Making the Final Decision

With all the information in hand, it’s time to make your decision. Here’s what to consider:

- Industry expertise and portfolio

- Certifications and quality assurance processes

- Production capacity and pricing

- Communication and willingness to collaborate

- Facility capabilities and professionalism

Weigh the pros and cons of each fabricator to select the one that aligns best with your project requirements, budget, and timeline.

FAQs

Here are some answers to frequently asked questions about selecting a glass fabrication service:

What certifications should I look for in a fabricator?

Look for compliance with industry standards, such as ISO certifications, safety glazing certifications (e.g., SGCC), and energy performance certifications.

How can I ensure the glass meets safety standards?

Ask for documentation on impact testing (for tempered and laminated glass) and fire-rating certifications, if applicable.

What should I prioritize, quality or cost?

While cost is an essential consideration, prioritize quality to avoid potential issues such as durability risks or rework costs down the line.

How soon should I engage a fabricator during project planning?

It’s ideal to engage a fabricator early in the design phase to ensure technical feasibility and avoid delays.

Can custom glass work be completed within tight deadlines?

A fabricator with efficient production processes and adequate capacity can accommodate tight deadlines. Be upfront about your timeline when requesting quotes.

Elevate Your Project with Expert Custom Glass Fabrication

Choosing the right glass fabricator is about more than ticking boxes. It’s about finding a partner who shares your vision and commitment to quality. At Huize Glass, we specialize in comprehensive customization and exceptional craftsmanship to ensure your projects stand out.

Our experienced team, cutting-edge techniques, and customer-focused approach guarantee products that exceed your expectations in both performance and aesthetics. Contact us today for a quote and see how we can bring your architectural vision to life.

Call us today at +86-769-38935799 or email us at sales@huizeglass.com

Related News