Insulated Glass Units (IGUs) Factory: Tailored Solutions

发布时间:

2025-10-14 14:32

来源:

huizeglass

Key Highlights

- Insulated glass units (IGUs) significantly improve a building's energy efficiency.

- They consist of two or more glass panes separated by a sealed, gas-filled space to reduce heat loss.

- An IGU factory follows a precise process of cutting, sealing, and gas-filling to create these high-performance units.

- Key benefits include lower energy bills, increased comfort, and sound insulation.

- Custom solutions are available to meet specific architectural and performance needs.

- Specialty options like Low-E and fire-rated IGUs offer enhanced properties.

Introduction

Windows connect us to the outside world, but they can also be a major source of energy loss in your home or office. Conditioned air can easily escape, leading to higher energy bills. Fortunately, modern technology offers a powerful solution: insulated glass. These advanced glass units are designed to provide excellent thermal performance, boosting energy efficiency without sacrificing natural light. They are a smart choice for any new construction or renovation project, helping you create a more comfortable and sustainable space.

Understanding Insulated Glass Units (IGUs)

Insulated glass units (IGUs) play a vital role in modern building design, enhancing both energy efficiency and occupant comfort. Comprised of multiple panes of glass separated by inert gases like argon or krypton, these units significantly reduce heat transfer. Their design minimizes issues such as air leakage and thermal bridging, allowing for better insulation on cold winter days. For personalized solutions, our friendly team is ready to help! Contact us to discuss your custom needs today.

What Sets IGUs Apart from Single or Double Glass

A single pane of glass offers very little insulation. It acts as a direct bridge for heat to travel, making it easy for your heated or cooled air to escape. This is why rooms with older, single-pane glass windows often feel drafty and are expensive to keep comfortable.

You may have heard the term "double glazing glass," which refers to having two layers of glass. However, an IGU is more than just two panes of glass. It is a hermetically sealed, single unit manufactured with specific components designed to work together. This sealed system is what provides the superior thermal insulation.

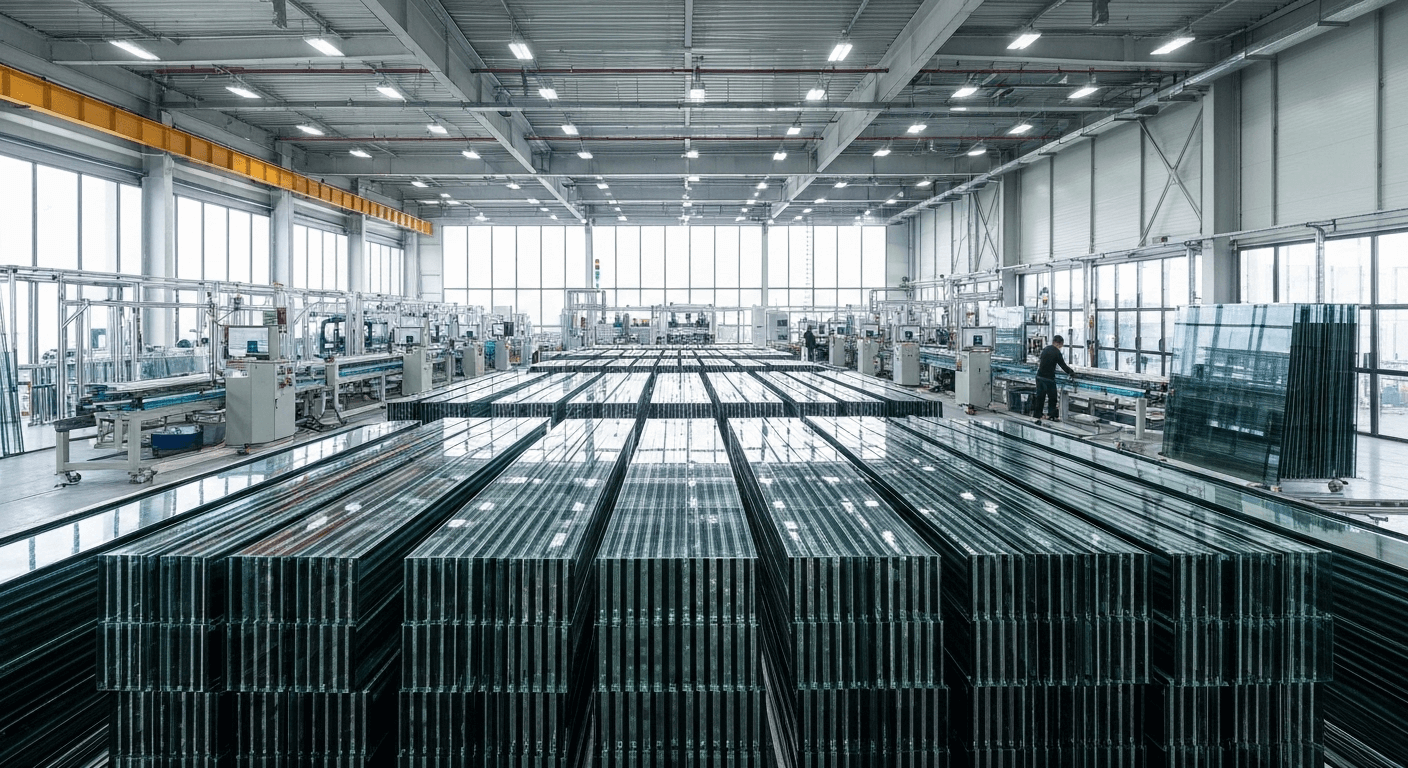

This is where an IGU factory differs from a regular glass supplier. A standard glass manufacturer might cut panes of glass to size, but an IGU factory specializes in the entire assembly process. They handle the precise spacing, sealing, and gas-filling required to create a durable, high-performance insulated glass unit that delivers on its promises of efficiency and comfort.

How IGUs Deliver Superior Insulation

The "magic" of an IGU lies in how it interrupts the flow of heat. A solid material like glass can easily transfer heat, creating a "thermal bridge" between the inside and outside. By creating a gap between the glass panes, an IGU effectively breaks this bridge.

This gap is typically filled with an insulating gas, which provides even better insulation than air alone. These gases are much denser than air, which means they are less likely to conduct heat. This slows down the transfer of hot or cold air between the inside and outside of your building.

Here’s how the components work together for better insulation:

- The Air Space: Creates a thermal break that disrupts the direct path for heat transfer.

- The Insulating Gas: Gases like argon or krypton are dense and poor heat conductors, significantly boosting insulation.

- The Seal: Keeps the gas in and moisture out, ensuring the unit performs effectively for years.

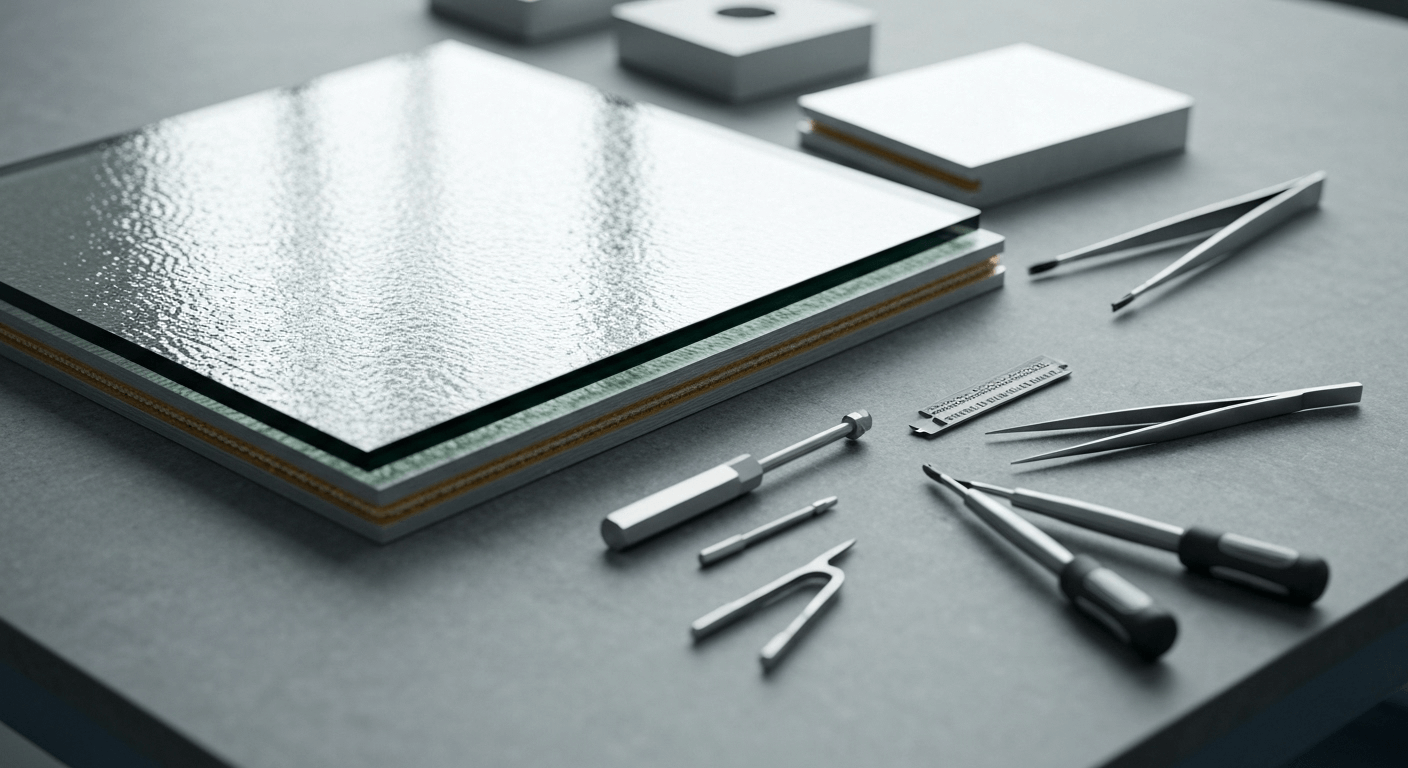

Main Components Used in IGU Manufacturing

An insulated glass unit is more than just glass; it's a system of carefully chosen components working in harmony. The main parts of any IGU include the glass panels themselves, spacer bars, desiccants to absorb moisture, and the gas filling that provides the crucial thermal break.

Each of these components plays a vital role in the unit's overall performance and longevity. Understanding what they are and what they do can help you appreciate the engineering behind these energy-saving windows. Let's explore the types of glass panels used and then the other critical parts.

Glass Panel Types and Their Properties

The type of glass used for the panels, or "lites of glass," has a major impact on the IGU's final properties. The thickness of the glass can be varied for strength and sound insulation, but the glass type itself offers unique benefits. For example, tempered glass is much stronger than standard glass and is considered a safety glass.

Another popular option is glass with low emissivity coatings (Low-E). This microscopic layer reflects heat, keeping your building cooler in the summer and warmer in the winter. Different types of glass can even be combined in a single unit to achieve specific goals like enhanced safety and energy efficiency.

Here is a simple breakdown of common glass panel types:

| Glass Type | Key Property |

|---|---|

| Float Glass | Standard, clear glass used as a base for many products. |

| Tempered Glass | Heat-treated for increased strength and safety. |

| Laminated Glass | Two or more panes bonded together for superior safety and security. |

| Low-E Glass | Coated to reflect heat and improve thermal performance. |

Spacer Bars, Desiccants, and Gas Fillings Explained

Beyond the glass, the other components are essential for a functioning IGU. Spacer bars are placed around the perimeter of the glass to create the consistent air space between the panes. These can be made of materials like aluminum or structural foam.

Inside the spacer bar, you'll find desiccants. This is a material, like silica gel, that absorbs any moisture trapped within the air space during manufacturing. This prevents fogging or condensation from forming between the panes, ensuring a clear view for the life of the unit.

Finally, the space is filled with an inert gas. While air can be used, most modern IGUs use a gas for better performance.

- Argon Gas: This is the most common choice due to its excellent thermal performance and affordability.

- Krypton Gas: Even more efficient than argon, krypton is a premium option used when maximum insulation is required in a thinner unit.

The IGU Factory Process: Step-by-Step Overview

Creating a high-quality IG unit is a precise and controlled manufacturing process. It starts with large glass sheets that are cut to the exact specifications required for a project. These pieces are then thoroughly cleaned and inspected before moving to the assembly line.

The production process involves carefully assembling the components, sealing them to be airtight, and filling them with gas. Throughout this journey, multiple quality checks are performed to ensure every unit meets strict performance standards. Let's look at the key steps in more detail.

Cutting and Assembling Glass Sheets

The first stage in the IGU factory is cutting. Large, raw glass sheets are loaded onto automated cutting tables. Based on the project's requirements, the machine scores and cuts the glass into the precise pieces of glass needed for the window panes. This ensures a perfect fit and minimizes waste.

Once cut, each pane is carefully washed and dried in a specialized machine to remove any dust, oil, or debris. A clean surface is absolutely critical for achieving a strong, durable seal later in the process. Any contaminant could compromise the integrity of the entire unit.

After cleaning, the panes are ready for assembly. They are paired up with a spacer frame, which has already been prepared with desiccant inside. The components are brought together in a controlled environment to begin forming the final insulated glass unit.

Sealing, Filling, and Final Quality Checks

Sealing is one of the most critical steps. A primary sealant like butyl is applied to the spacer to create an airtight and watertight barrier. After the panes are pressed together, a secondary sealant, often a silicone sealant, is applied around the entire outside edge of the unit. This provides structural strength and a final layer of protection.

Once the unit is sealed, the gas filling process begins. Small holes in the spacer allow the factory to pump out the air and inject the insulating gas, such as argon. The holes are then plugged and sealed to lock the gas inside permanently.

Throughout the process, and especially at the end, rigorous quality checks are performed to guarantee performance. These checks ensure:

The seals are perfect with no potential for leaks.

The gas concentration is at the correct level for optimal insulation.

There are no visual defects, scratches, or moisture inside the unit.

Popular Types of IGUs Available for Custom Order

Insulated glass units are incredibly versatile and can be tailored to meet a wide range of needs. Beyond the standard double-pane unit, you can order a custom IGU with specialized properties for enhanced performance, safety, or aesthetics. Popular options include Low-E glass, laminated glass, and even fire-rated IGUs.

These custom options allow architects and builders to solve specific challenges without compromising on energy efficiency. Whether you need extra UV protection, enhanced security, or compliance with fire codes, there is an IGU solution available. Are you looking for a custom solution? Contact us at Huize Glass to discuss your project needs.

Low-E Insulated Glass Units for Enhanced Energy Efficiency

Low-E glass, which stands for low emissivity, is a game-changer for energy efficiency. This type of glass has an ultra-thin, transparent metallic coating that reflects thermal energy. When used in an IGU, this coating works year-round to improve comfort and deliver significant energy savings.

In the winter, the Low-E coating reflects heat from your furnace back into the room, reducing heat loss through the window. In the summer, it reflects the sun's heat away from the window, keeping your home cooler and reducing the strain on your air conditioner.

This technology offers several key advantages:

- Energy Savings: Lowers heating and cooling costs by improving insulation.

- UV Protection: Blocks a significant portion of harmful UV rays, which can fade furniture, carpets, and artwork.

- Improved Comfort: Reduces cold spots near windows in the winter and helps maintain a consistent indoor temperature.

Fire-Rated and Laminated IGU Options

Safety and code compliance are critical in many building projects, and specialized IGUs are available to meet these needs. A fire-rated IGU is designed to withstand extreme heat and act as a barrier to flames and smoke for a specified period. This is essential for certain walls, doors, and corridors in commercial and multi-family buildings.

These units are constructed with special glass and sealing techniques that can handle severe thermal stress without breaking. This provides precious time for occupant evacuation and for firefighters to respond in an emergency.

Laminated glass is another type of safety glass that can be incorporated into an IGU. It consists of two or more glass panes bonded together by a durable interlayer. If the glass breaks, the fragments stick to the interlayer instead of shattering, reducing the risk of injury. This also provides an added layer of security against forced entry.

IGUs for Homes and Commercial Buildings: Key Benefits

Whether you're building a new home or upgrading a commercial property, insulated glass units offer a host of compelling benefits. The most significant advantage is energy savings, but the improvements don't stop there. IGUs also enhance occupant comfort and provide effective sound insulation.

By controlling factors like solar heat gain, these units help create a more stable and pleasant indoor environment. The following sections will explore these advantages in greater detail, showing why IGUs are a smart investment for any building.

Energy Savings, Comfort, and Noise Reduction

The primary reason many people choose IGUs is to lower their energy costs. Because an IGU is a better insulator than a single pane of glass, it prevents your heated or cooled air from escaping. This means your air conditioner and furnace run less often, leading to a noticeable reduction in your monthly energy bill.

Beyond savings, IGUs greatly improve occupant comfort. They eliminate the cold drafts commonly felt near old windows in the winter and reduce the intense heat that radiates from windows in the summer. This creates a more consistent and cozy temperature throughout your space, no matter the season.

Another often-overlooked benefit is noise reduction. The multiple layers of glass and the sealed air space work together to dampen outside sounds. This can make a huge difference in creating a quieter, more peaceful indoor environment, especially if you live near a busy street or in a noisy neighborhood.

Lower energy bills

More consistent indoor temperatures

A quieter indoor environment

Custom Design Solutions for Unique Architectural Needs

Modern architecture often features large, unique, or complex window designs. An IGU factory can provide custom design solutions to meet these specific architectural needs without sacrificing performance. Whether you need oversized panels, curved glass, or specific glass combinations, a custom IGU can be manufactured to your exact specifications.

These bespoke design solutions allow you to achieve your aesthetic vision while still meeting or exceeding energy codes. You can select the glass type, thickness, coatings, and gas fill to create a unit that perfectly balances appearance with thermal performance and other functional requirements.

If your project has unique requirements, don't settle for a one-size-fits-all product. Working directly with a manufacturer ensures you get the right advice and the perfect custom IGU for your building. For a consultation on your unique architectural needs, contact the experts at Huize Glass today. We specialize in creating tailored glass solutions.

Conclusion

In summary, Insulated Glass Units (IGUs) offer remarkable benefits for both residential and commercial applications, from energy efficiency to enhanced comfort. Understanding the unique components and manufacturing processes behind IGUs allows you to make informed decisions when selecting the right solutions for your needs. Custom designs can cater to specific architectural requirements, ensuring that your space not only looks great but also performs exceptionally well. If you're looking for tailored IGU solutions or have any questions, don't hesitate to get in touch with us for expert advice and support tailored to your project.

Frequently Asked Questions

How long do IGUs last, and can they be repaired or must they be replaced?

An insulated glass unit is very difficult to repair. If the seal fails, the insulating gas escapes and moisture can get inside, causing fogging. At this point, the unit loses its energy savings benefits. The only effective solution is a full replacement of the IG unit to restore its performance.

How do IGU factories guarantee consistent product quality?

An IGU factory ensures quality through a controlled production process. This includes using high-grade materials, precise assembly, proper sealing, and correct insulating gas fill levels. Multiple quality checks are performed at each stage to guarantee every unit provides maximum energy efficiency and durability before it leaves the factory.

Where can I order custom IGUs or get expert advice? (with CTA to contact us)

For expert advice and to order a custom IGU tailored to your project's specific needs, it's best to work with a specialized manufacturer. The team at Huize Glass is ready to help. Contact us today to discuss your requirements and get a quote for your custom glass solution.

Related News